Automation systems for all requirements

The demands on modern machines and plants are steadily growing in all industries. With the automation systems from Siemens, you can cover all requirements while benefiting from maximum efficiency, flexibility, and cost effectiveness.

- SIMATIC controllers

- SIMATIC I/O Systems

- SIMATIC Motion Control

- SIMATIC Control Systems

- Software for SIMATIC Controllers

- SIMATIC Field PG

SIMOTION is a drive control system from Siemens. Benefit from a coordinated portfolio of system hardware and software.

SIMOTION Hardware

SIMOTION offers you two hardware platforms for your application: SIMOTION D for drive-based motion control, and SIMOTION C for PLC-based motion control. The hardware platforms always have the same system characteristics. You decide which hardware is best suited to your machine.

SIMOTION Software

The scalable Runtime system ensures the right functionality for your mechanical engineering tasks. You can use the SCOUT Engineering System to configure your SIMOTION project, and SCOUT TIA also allows you to do so fully integrated in the TIA Portal. In addition, SIMOTION supports you with a modular technology object approach, object-oriented programming (OOP) and a modular programming model with Units. Read More…

Boosting productivity in CNC production

SIMATIC TOP connect – innovative and efficient system cabling

SIMATIC PCS 7 and SIMATIC PCS neo, we have exactly the right solution for your area of application. Both systems rely on the same innovative and robust hardware platform and a uniform system architecture. Thus, we offer you maximum flexibility, reliability, and efficiency. Take advantage of this innovative technology to protect your knowledge and investments, improve existing processes, or make new ideas a reality – today, tomorrow, and beyond. Read More…

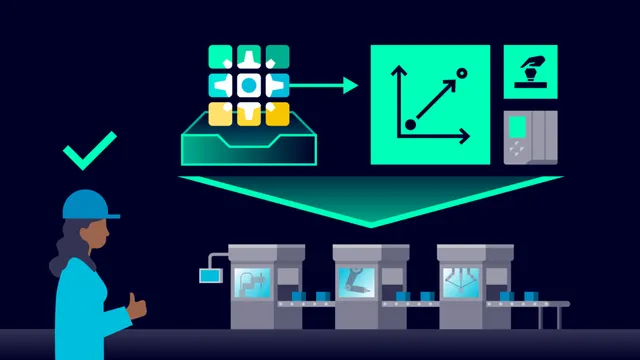

Totally Integrated Automation (TIA)

Totally Integrated Automation (TIA) offers smart automation development, flexible machine concepts, transparent operation, and sustainable solutions that enable access to data to calculate and optimize the product carbon footprint. We are constantly improving and expanding TIA to be future-proof and adaptive to existing and upcoming challenges.

challenges of today and tomorrow

The Future of Automation

TIA is gradually integrating new technologies, such as artificial intelligence (AI), In order to meet challenges such as the skills shortage, supply volatility, scarce resources and the need for greater sustainability, automation will be more flexible, sustainable and resilient in the future. Discover what we are already exploring and tackling to accelerate the digital transformation towards more autonomy in a human centric way to master all these challenges.